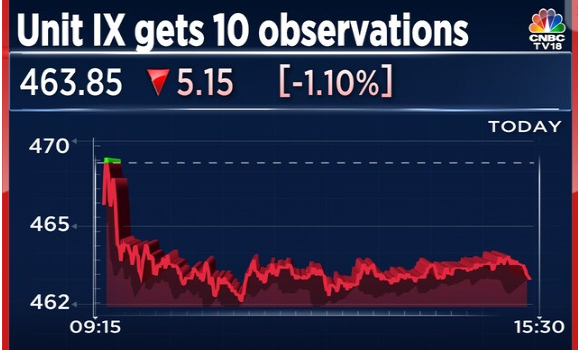

U.S. FDA Issues the pharmaceutical industry, regulatory compliance plays a crucial role in ensuring the safety, efficacy, and quality of drugs and their active pharmaceutical ingredients (APIs). Regulatory bodies like the U.S. Food and Drug Administration (FDA) closely monitor companies manufacturing APIs to ensure they meet stringent global standards. Recently, the U.S. FDA issued 10 observations to an API manufacturing unit of Aurobindo Pharma, a leading pharmaceutical company headquartered in India.

This article will provide an in-depth analysis of the FDA’s observations, the potential implications for Aurobindo Pharma’s API unit, and the broader regulatory challenges facing the pharmaceutical industry. We will also explore the significance of compliance with FDA regulations and the steps Aurobindo Pharma can take to address these observations and safeguard its reputation in the global market.

Overview of Aurobindo Pharma and Its API Unit

Aurobindo Pharma is a prominent global pharmaceutical company that manufactures a wide range of products, including APIs, formulations, and over-the-counter (OTC) drugs. The company has a strong international presence and exports its products to more than 150 countries. The API unit plays a critical role in the company’s supply chain by producing the raw materials used to create finished pharmaceutical products.

APIs are the biologically active components of a drug that produce the intended therapeutic effect. The quality and consistency of APIs are crucial to ensuring that the final drug is safe and effective for patients. This is why regulatory authorities, including the U.S. FDA, conduct regular inspections of API manufacturing facilities to ensure compliance with good manufacturing practices (GMP) and other quality standards.  For the more information click on this link

For the more information click on this link

What are FDA Observations?

Before diving into the specifics of the 10 observations issued to Aurobindo Pharma, it’s essential to understand what FDA observations are and how they impact pharmaceutical companies. When the FDA inspects a manufacturing facility, it looks for any deviations from established quality standards and regulations. If the inspectors identify any areas of concern or non-compliance, U.S. FDA Issues they issue observations, which are listed on a Form 483.

The observations noted on Form 483 are not final regulatory actions. Instead, they serve as a warning to the company that certain practices or conditions need to be corrected. The company is expected to respond to the FDA’s observations within a specified timeframe, U.S. FDA Issues outlining its plan to address the issues and bring the facility into compliance.

If a company fails to take appropriate corrective actions, the FDA may escalate its enforcement measures, which can include issuing warning letters, imposing import alerts, U.S. FDA Issues or pursuing legal action. In the case of Aurobindo Pharma, the 10 observations are a signal that the company must take immediate steps to rectify the identified deficiencies.

Details of the FDA’s 10 Observations to Aurobindo’s API Unit

While the specific details of the FDA’s 10 observations have not been publicly disclosed, common issues that the FDA typically highlights in its observations include:

- Inadequate Documentation and Record-Keeping: The FDA may observe that a company’s documentation practices do not meet GMP standards. This can include incomplete, inaccurate, or missing records related to production, testing, and quality control.

- Deviations from Standard Operating Procedures (SOPs): The FDA may note instances where the company failed to follow established SOPs for manufacturing or quality control, leading to inconsistencies in the production process.

- Equipment Maintenance Issues: Proper maintenance and calibration of equipment are essential to ensure the consistent quality of APIs. FDA inspectors may flag equipment that is not being properly maintained or calibrated, U.S. FDA Issues which can lead to contamination or variation in product quality.

- Inadequate Quality Control Systems: A robust quality control system is vital for detecting and addressing potential issues during the production process. The FDA may observe that the company’s quality control measures are insufficient or not implemented correctly.

- Failure to Investigate Deviations or Non-Conformances: When deviations from established procedures occur, companies are required to investigate and document the root cause. Failure to do so can lead to unresolved issues that affect product quality.

- Poor Cleaning and Sanitation Practices: The FDA may raise concerns about the cleanliness and sanitation of the manufacturing environment. Poor cleaning practices can lead to cross-contamination between different API batches.

- Inadequate Employee Training: Employees working in API manufacturing units must be properly trained in GMP requirements and SOPs. The FDA may note that employees are not adequately trained, which can lead to errors in production.

- Failure to Validate Manufacturing Processes: The FDA requires companies to validate their manufacturing processes to ensure they consistently produce high-quality APIs. If the validation process is incomplete or insufficient, the FDA may issue an observation.

- Improper Handling of Raw Materials and Intermediates: The FDA may observe that raw materials or intermediates used in the production of APIs are not stored, handled, U.S. FDA Issues or tested according to established procedures, leading to potential contamination or degradation.

- Inconsistent Quality Testing: Inconsistent or inadequate testing of APIs for potency, purity, and stability can result in substandard products reaching the market. The FDA may note deficiencies in the company’s testing protocols or the reliability of its results.

Implications of the FDA’s Observations for Aurobindo Pharma

The issuance of 10 observations by the FDA to Aurobindo Pharma’s API unit is a serious matter that could have significant consequences for the company’s operations and reputation. While observations themselves do not indicate an immediate halt in production, they highlight areas where the company must take corrective action to avoid further regulatory scrutiny.

1. Financial Impact

Addressing the FDA’s observations will likely require Aurobindo Pharma to invest in corrective measures, such as upgrading equipment, revising procedures, and providing additional employee training. These investments could lead to increased operational costs in the short term. Additionally, U.S. FDA Issues if the company experiences delays in production or faces challenges in obtaining new product approvals, it could see a negative impact on its revenue.

2. Reputational Damage

FDA observations can also damage a company’s reputation, particularly if they are related to quality control issues. Aurobindo Pharma is a globally recognized brand, and any indication of non-compliance with regulatory standards could erode the trust of healthcare professionals, patients, U.S. FDA Issues and business partners.

Pharmaceutical companies rely heavily on their reputation for quality and reliability, U.S. FDA Issues and any concerns about compliance can have long-term effects on their market position. Aurobindo Pharma will need to take swift and decisive action to reassure stakeholders that it is committed to maintaining the highest standards of quality and safety.

3. Delays in Regulatory Approvals

For companies like Aurobindo Pharma that depend on regulatory approvals to launch new products or enter new markets, FDA observations can lead to delays. If the FDA has concerns about the quality of APIs produced at the facility, U.S. FDA Issues it may withhold approvals for new products until the issues are resolved.

In the case of Aurobindo Pharma, this could potentially delay the launch of new drugs or affect the company’s ability to supply existing products to key markets like the U.S. This could have a ripple effect on the company’s overall growth and profitability.  For the more information click on this link

For the more information click on this link

4. Escalation to Warning Letters or Import Alerts

If Aurobindo Pharma does not take adequate corrective action in response to the FDA’s observations, the situation could escalate. The FDA may issue a warning letter, which is a formal notice of non-compliance, or place the company’s products on an import alert, U.S. FDA Issues effectively barring them from being sold in the U.S. market until the issues are resolved.

Such actions could have severe financial and operational consequences for Aurobindo Pharma, particularly given the importance of the U.S. market for its business.

Aurobindo Pharma’s Response: Steps Toward Remediation

In response to the FDA’s observations, Aurobindo Pharma must take swift and comprehensive corrective actions to address the identified deficiencies. The company will need to develop a detailed plan for remediation and ensure that it fully complies with GMP standards.

1. Root Cause Analysis and Corrective Action Plan

Aurobindo Pharma will need to conduct a thorough root cause analysis to identify the underlying reasons for the FDA’s observations. Based on this analysis, U.S. FDA Issues the company should develop a corrective action plan that addresses each observation in detail. The plan should include specific timelines for implementing corrective measures and improving processes.

2. Strengthening Quality Control and Documentation Practices

One of the key areas of focus for Aurobindo Pharma will likely be strengthening its quality control systems and ensuring that all documentation is accurate, complete, and in compliance with FDA standards. This may involve implementing new procedures for record-keeping, enhancing testing protocols, U.S. FDA Issues and ensuring that all deviations are properly investigated and documented.

3. Employee Training and Awareness

Ensuring that employees are adequately trained in GMP requirements is critical to preventing future compliance issues. Aurobindo Pharma may need to provide additional training sessions for its employees to ensure they are fully aware of the FDA’s expectations and the importance of following established procedures.

4. Facility Upgrades and Process Validation

If the FDA’s observations relate to equipment or process validation, Aurobindo Pharma may need to invest in upgrading its facilities and validating its manufacturing processes to meet current regulatory standards. This could involve purchasing new equipment, improving cleaning and sanitation procedures, U.S. FDA Issues and conducting more rigorous testing to ensure product quality.

5. Engaging with the FDA

Throughout the remediation process, Aurobindo Pharma must maintain open communication with the FDA. The company will need to submit regular updates on its progress in addressing the observations and provide any additional information requested by the FDA.

The Broader Impact on the Pharmaceutical Industry

The FDA’s observations at Aurobindo Pharma’s API unit highlight the importance of regulatory compliance for the pharmaceutical industry as a whole. The pharmaceutical industry is one of the most heavily regulated sectors in the world, U.S. FDA Issues and companies must adhere to strict standards to ensure the safety and efficacy of their products.

Regulatory compliance is not only a legal requirement but also a critical factor in maintaining public trust and ensuring the availability of safe and effective medicines. The case of Aurobindo Pharma serves as a reminder to all pharmaceutical companies of the importance of robust quality control systems, U.S. FDA Issues regular audits, and ongoing employee training.

Conclusion

The U.S. FDA’s issuance of 10 observations to Aurobindo Pharma’s API unit underscores the challenges and responsibilities that pharmaceutical companies face in maintaining regulatory compliance. While the observations are not an immediate cause for alarm, they signal the need for Aurobindo Pharma to take swift and comprehensive corrective actions to address the identified deficiencies.

By implementing a robust corrective action plan, strengthening its quality control systems, and maintaining open communication with the FDA, Aurobindo Pharma can resolve the issues and continue to deliver high-quality APIs to the global market. Ultimately, U.S. FDA Issues regulatory compliance is a continuous process, and companies must remain vigilant to ensure they meet the highest standards of quality, safety, and efficacy in the pharmaceutical industry. ALSO READ:- RBI Flags Irregularities in Grant of Gold Loans: Scrutiny of Lenders and Public Criticism 2024

скачать мостбет официальный сайт скачать мостбет официальный сайт .

motsbet https://www.mostbet6006.ru .

mostbet официальный сайт http://www.mostbet6006.ru .

1 вин вход в личный кабинет 1 вин вход в личный кабинет .

1 win.com https://familyclub.borda.ru/?1-6-0-00002163-000-0-0-1743051813/ .

мостбет кыргызстан mostbet6006.ru .

1 win pro http://balashiha.myqip.ru/?1-12-0-00000437-000-0-0-1743258848/ .

1wiun alfatraders.borda.ru/?1-0-0-00004932-000-0-0-1743258210 .

1win online https://1win6049.ru/ .

1win партнерская программа вход http://balashiha.myqip.ru/?1-12-0-00000437-000-0-0-1743258848 .

mostbet kg скачать на андроид https://svstrazh.forum24.ru/?1-18-0-00000136-000-0-0-1743260517/ .

скачат мостбет http://svstrazh.forum24.ru/?1-18-0-00000136-000-0-0-1743260517/ .

мостбет кыргызстан скачать https://svstrazh.forum24.ru/?1-18-0-00000136-000-0-0-1743260517 .

один вин https://www.obovsem.myqip.ru/?1-9-0-00000059-000-0-0-1743051936 .

1win. 1win6003.ru .

1 вин войти https://www.obovsem.myqip.ru/?1-9-0-00000059-000-0-0-1743051936 .

мостбет мобильная версия скачать мостбет мобильная версия скачать .

1 вин вход 1win6051.ru .

1 win http://1win6051.ru/ .

1win казино 1win казино .

1-win https://www.1win6004.ru .

один вин официальный сайт https://1win6051.ru/ .

wan win http://1win6052.ru .

mostbet промокод mostbet промокод .

mostbet kg http://mostbet6029.ru/ .

мостбет скачать мостбет скачать .

1win pariuri https://1win5004.ru .

1win http://1win6053.ru/ .

мрстбет мрстбет .

1win sports http://www.1win15.com.ng .

mostbet.kg https://mostbet6012.ru/ .

1win rossvya https://www.1win6009.ru .

скачать мостбет http://www.mostbet6012.ru .

Приобрести диплом университета по выгодной цене возможно, обратившись к проверенной специализированной фирме. Купить документ института можно в нашем сервисе. diplomidlarf.ru/kupit-diplom-s-provedeniem-v-reestr-3

пластиковые окна пластиковые окна .

download betwinner app http://www.betswinner.bet .

банкротство физ лиц банкротство физ лиц .

банкротство граждан bankrotstvo-grajdan.ru .

Оформиление дипломов ВУЗов по всей России и СНГ — с печатями, подписями, приложением и возможностью архивной записи (по запросу).

Документ максимально приближен к оригиналу и проходит визуальную проверку.

Мы даем гарантию, что в случае проверки документа, подозрений не возникнет.

– Конфиденциально

– Доставка 3–7 дней

– Любая специальность

Уже более 3075 клиентов воспользовались услугой — теперь ваша очередь.

Пишите — ответим быстро, без лишних формальностей.

Телеграм накрутка подписчиков бесплатно 2025 Телеграм накрутка подписчиков бесплатно

пластиковые окна с доставкой http://okna177.ru .

Thanks for the article. Here’s more on the topic https://cultureinthecity.ru/

Покупка дипломов ВУЗов по всей Украине — с печатями, подписями, приложением и возможностью архивной записи (по запросу).

Документ максимально приближен к оригиналу и проходит визуальную проверку.

Мы гарантируем, что в случае проверки документа, подозрений не возникнет.

– Конфиденциально

– Доставка 3–7 дней

– Любая специальность

Уже более 2418 клиентов воспользовались услугой — теперь ваша очередь.

Перейти — ответим быстро, без лишних формальностей.

Thanks for the article. Here’s more on the topic https://up-top.ru/

Thanks for the article. Here’s more on the topic https://l-spb.ru/

Website https://ipodtouch3g.ru/ .

Веб сайт https://urkarl.ru/

Website https://ipodtouch3g.ru/ .

Website https://church-bench.ru/ .

Веб сайт https://urkarl.ru/

Веб сайт https://urkarl.ru/

Веб сайт https://urkarl.ru/

Website https://portalbook.ru/arenda-avtomobilya-dlya-povsednevnyh-zadach-i-poezdok-po-gorodudlya-povsednevnyh-zadach-i-poezdok-po-gorodu/

En la Clínica de Urología Moderna se recoge todo lo que un hombre debe saber sobre salud urinaria y sexual.

Para conocer las opciones de cirugía urológica disponible, revisa la sección de servicios de la Clínica de Urología Moderna.

En la Clínica de Urología Moderna verás explicados los procedimientos quirúrgicos avanzados de forma sencilla.